Custom Unwinders

Types of unwinders

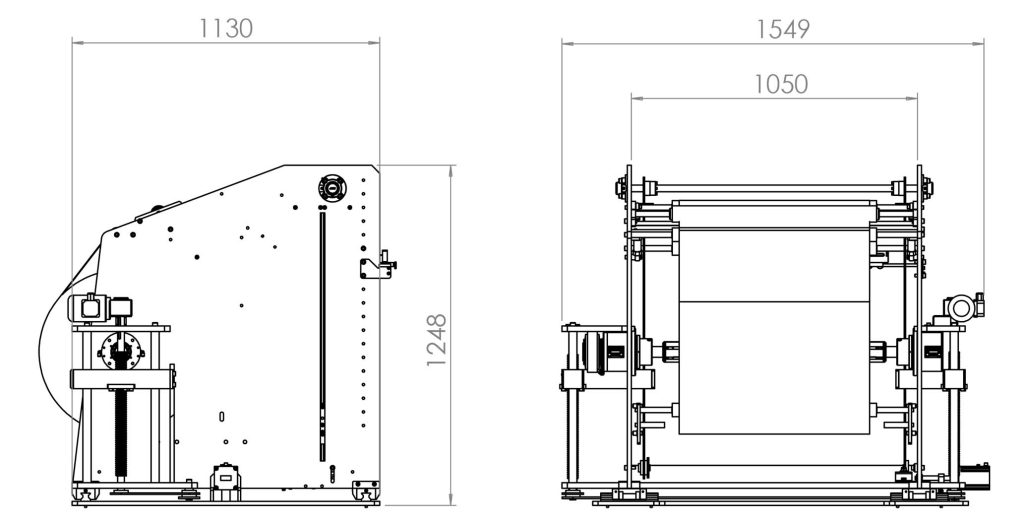

Double-supported unwinders (Medium-high reel weights) between 150 and 1000kg.

Single-support or cantilever unwinders (Medium-low reel weights) between 0 and 150kg.

Technical information

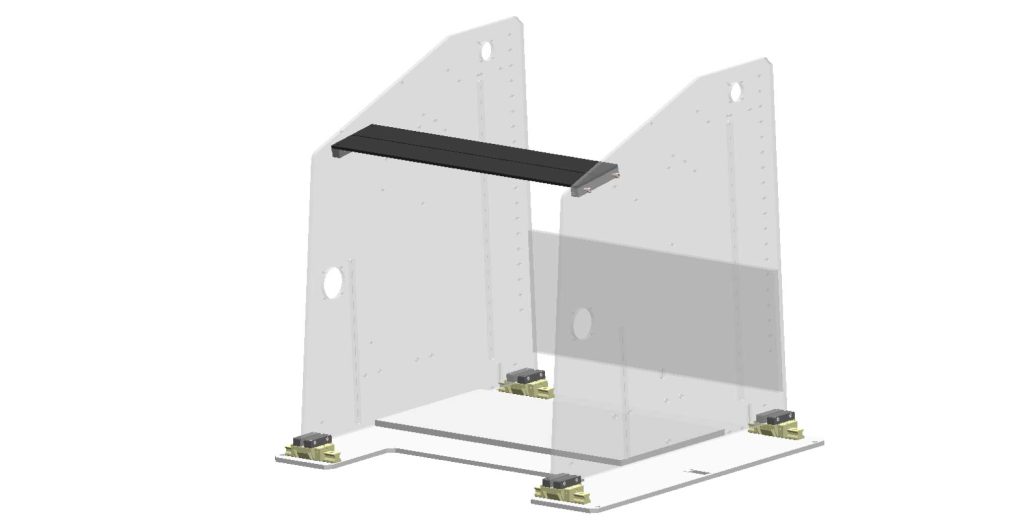

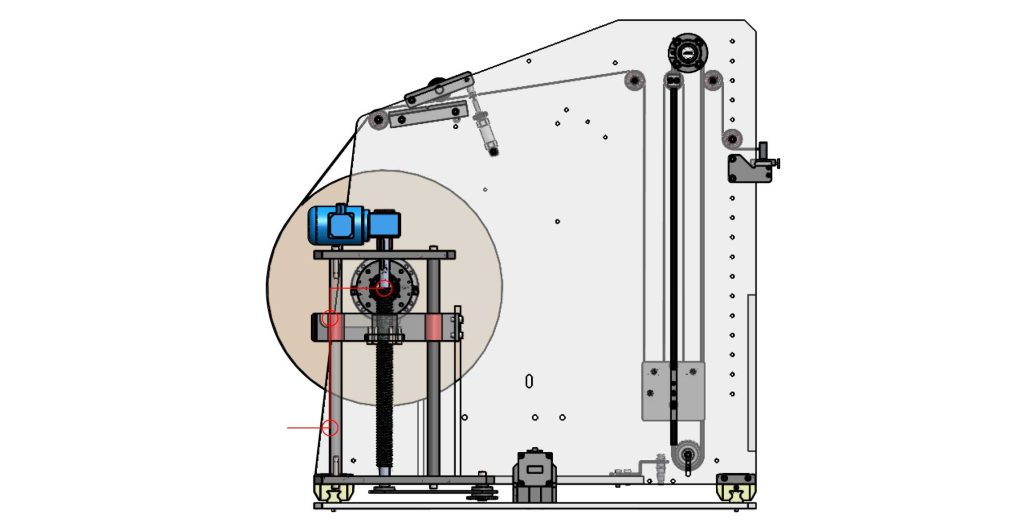

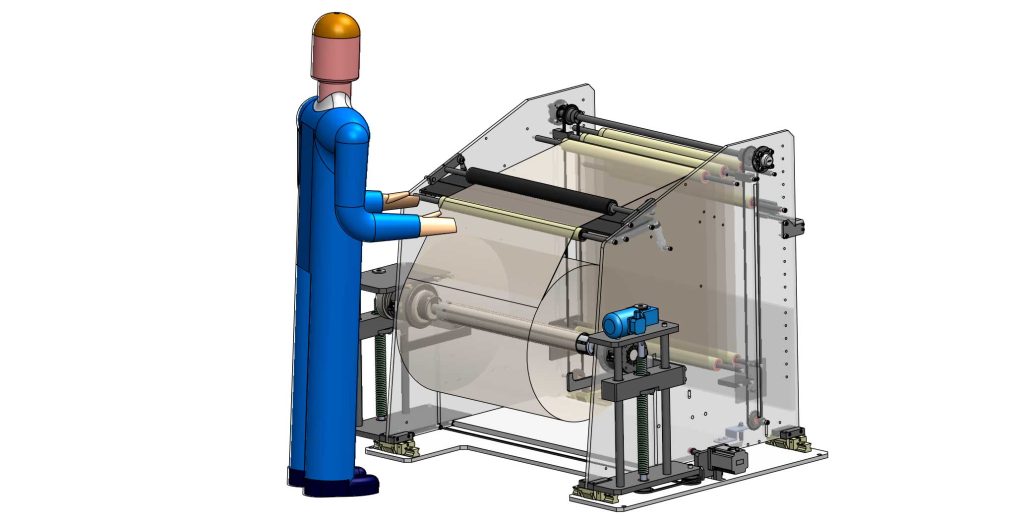

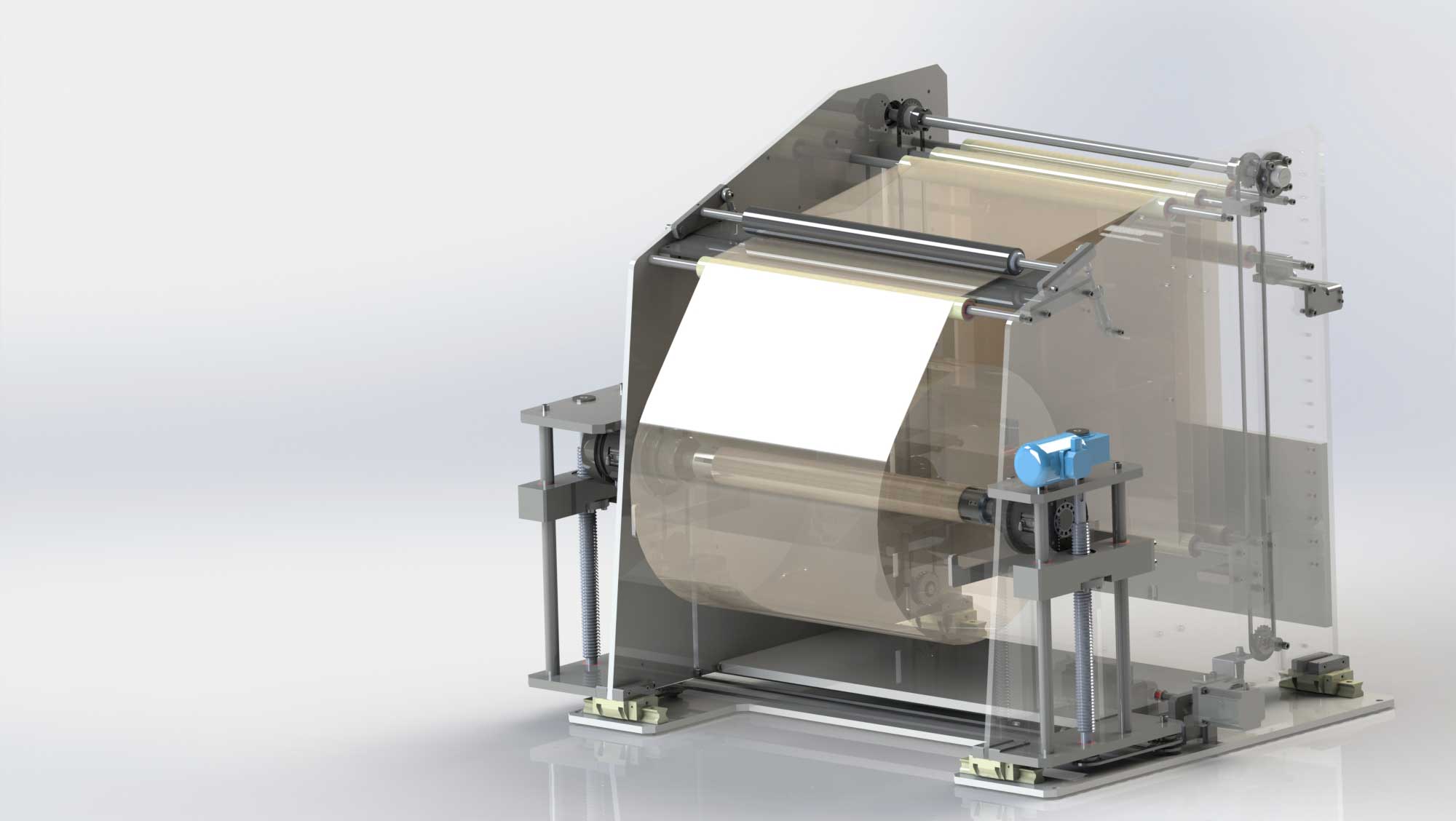

Reel loading and unloading

Our reel lifter has been designed to maximize the ease of reel handling, using a double-arm support system that operates with worm screws, positioned and geared on each side of the unwinder’s frames. This structure allows the operator to load and unload reels easily, efficiently, and safely. The lifter picks up the expanding shaft and the reel from the floor, raising it to the precise height. Once at the required height, the reel is smoothly transferred along the arms to the safety supports, where it is ready for operation. This system not only increases safety and reduces operator effort but also speeds up changeover times, optimizing efficiency in every production process.

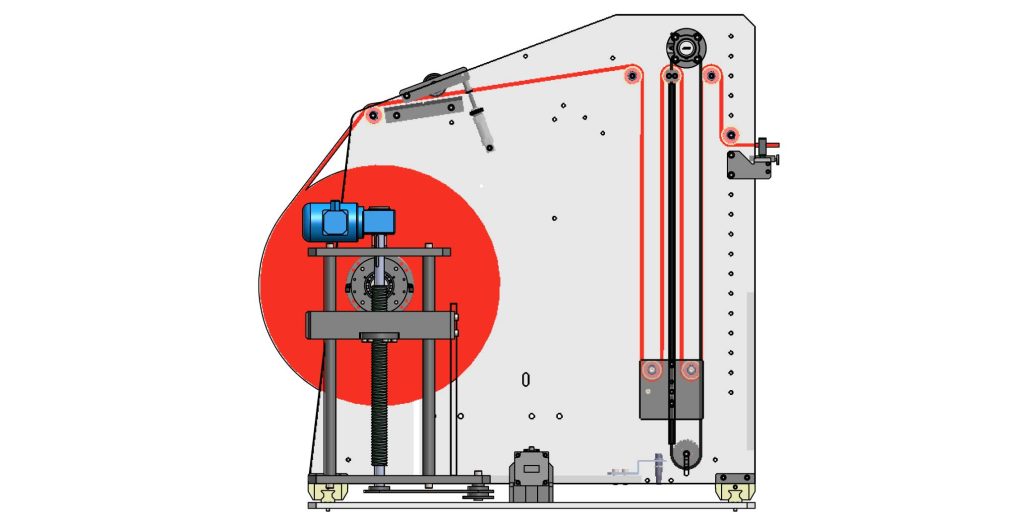

Threading

This system is designed to make web threading a comfortable and quick process. The frames have strategically placed windows for easy access and handling of the web, allowing for effortless manipulation. Additionally, the system includes a lifting and locking mechanism in the dancer’s movable part, allowing it to be lifted and secured in position for threading without the need to bend down. This design not only reduces the operator’s physical effort but also optimizes setup times and ensures an ergonomic posture, enhancing efficiency and safety at every stage of the process.

Web aligner

Our web aligner, available in automatic and manual versions, is designed to ensure a consistent horizontal position of the web during unwinding. This advanced system includes a horizontal position sensor, axial displacement servo, and movable frames with a ±50 mm adjustment range, all coordinated through high-precision control electronics. The system continuously adjusts the position of the frames based on the exact web location, achieving precise and stable alignment. This control ensures consistent quality during the unwinding process, reducing misalignments and optimizing the production line’s performance.

Web tension control

AUTOMATIC SPLICING

Our automatic splicing system allows seamless joining during the unwinding process, with an option for registration splicing for perfect alignment. The butt splicing technology prevents an increase in web thickness, ensuring uninterrupted continuity, which is essential for high-precision processes and subsequent production phases without disruptions. This system not only reduces material waste but also significantly minimizes machine downtime, making it ideal for high-production lines. It is the perfect solution for those looking to maximize their process efficiency and reduce reliance on manual intervention, enabling robust automation that ensures efficiency at every production stage.