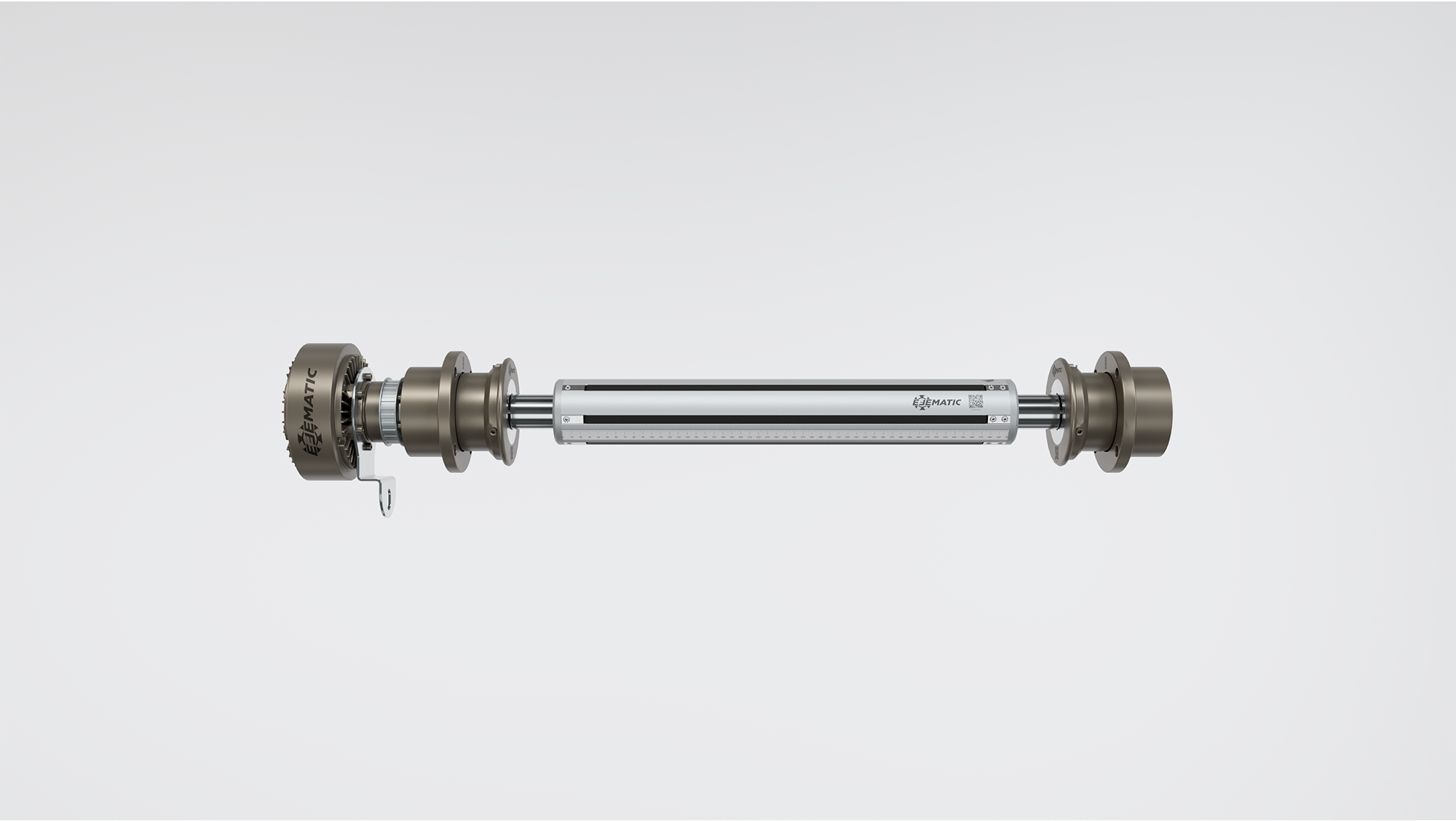

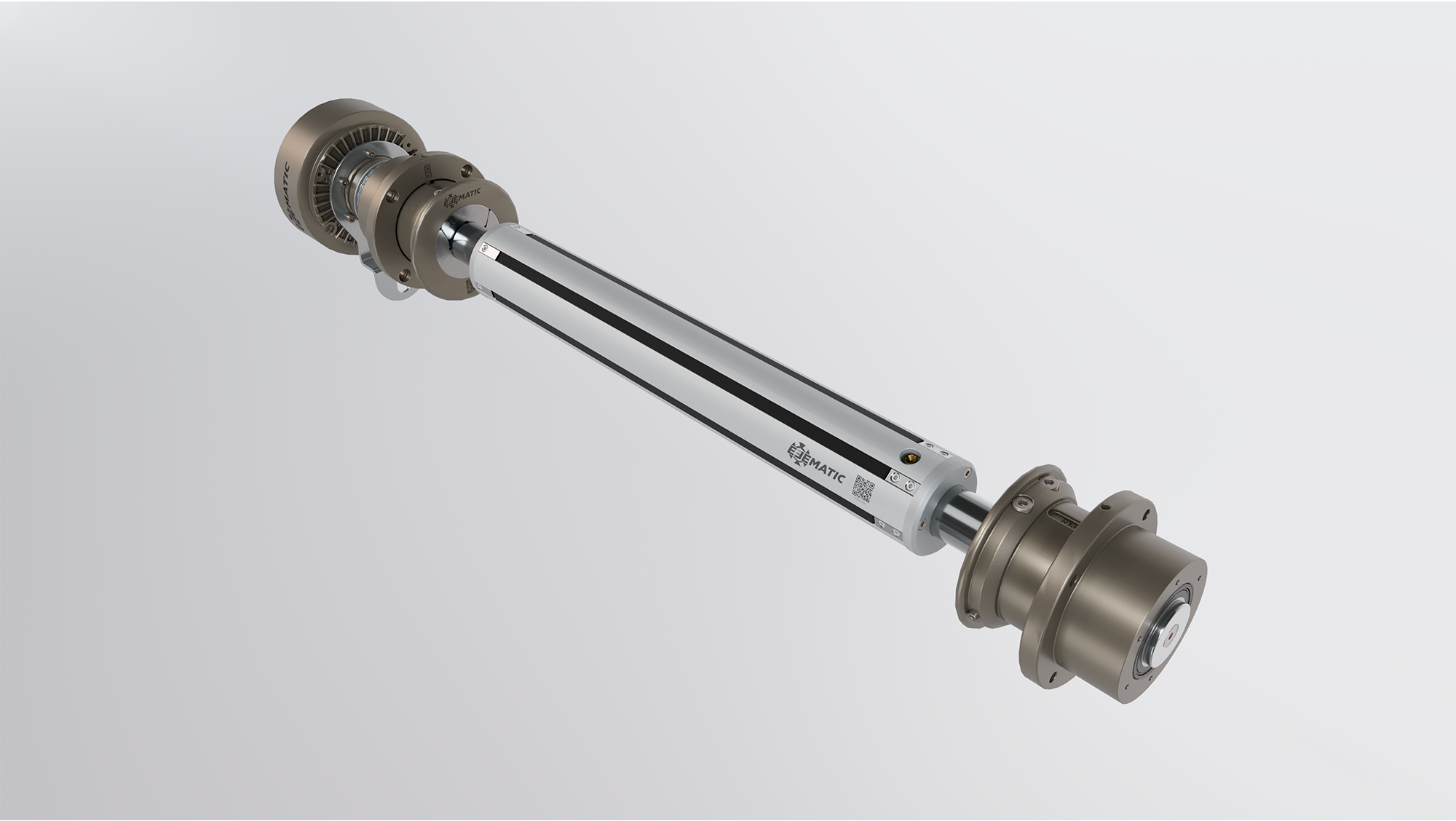

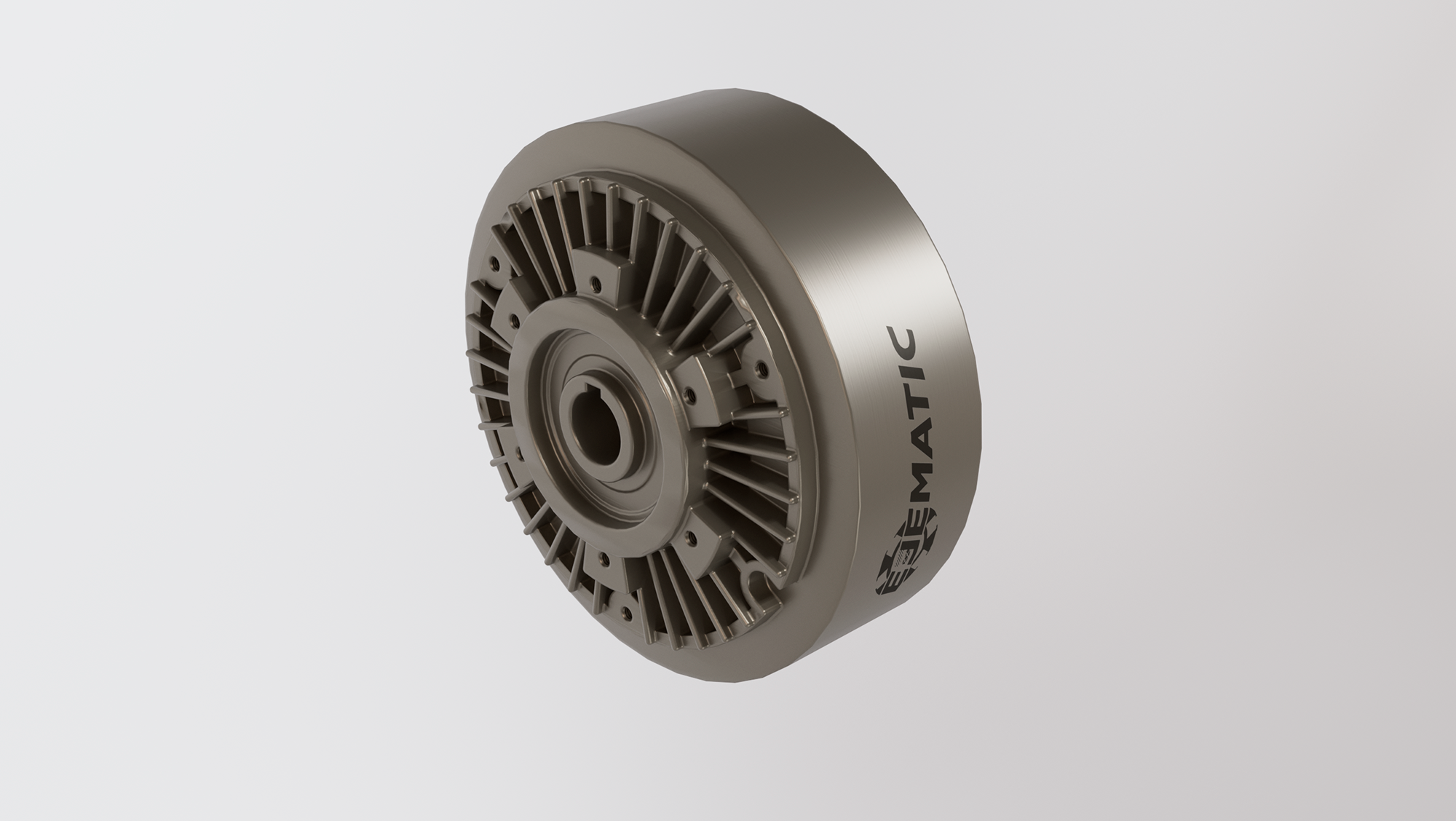

Electric Clutches

OPERATION

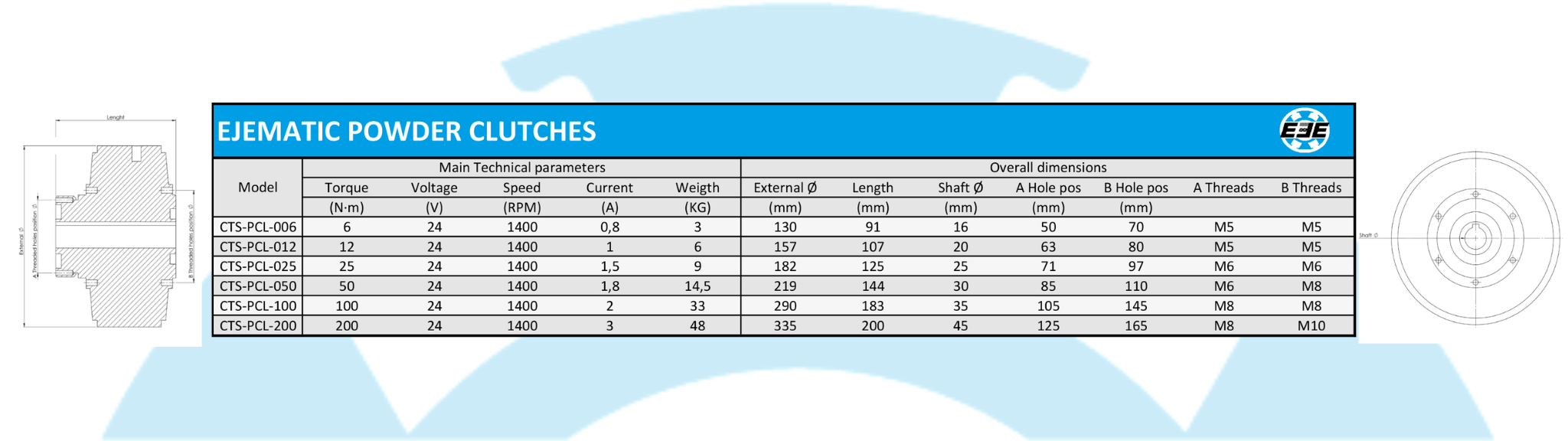

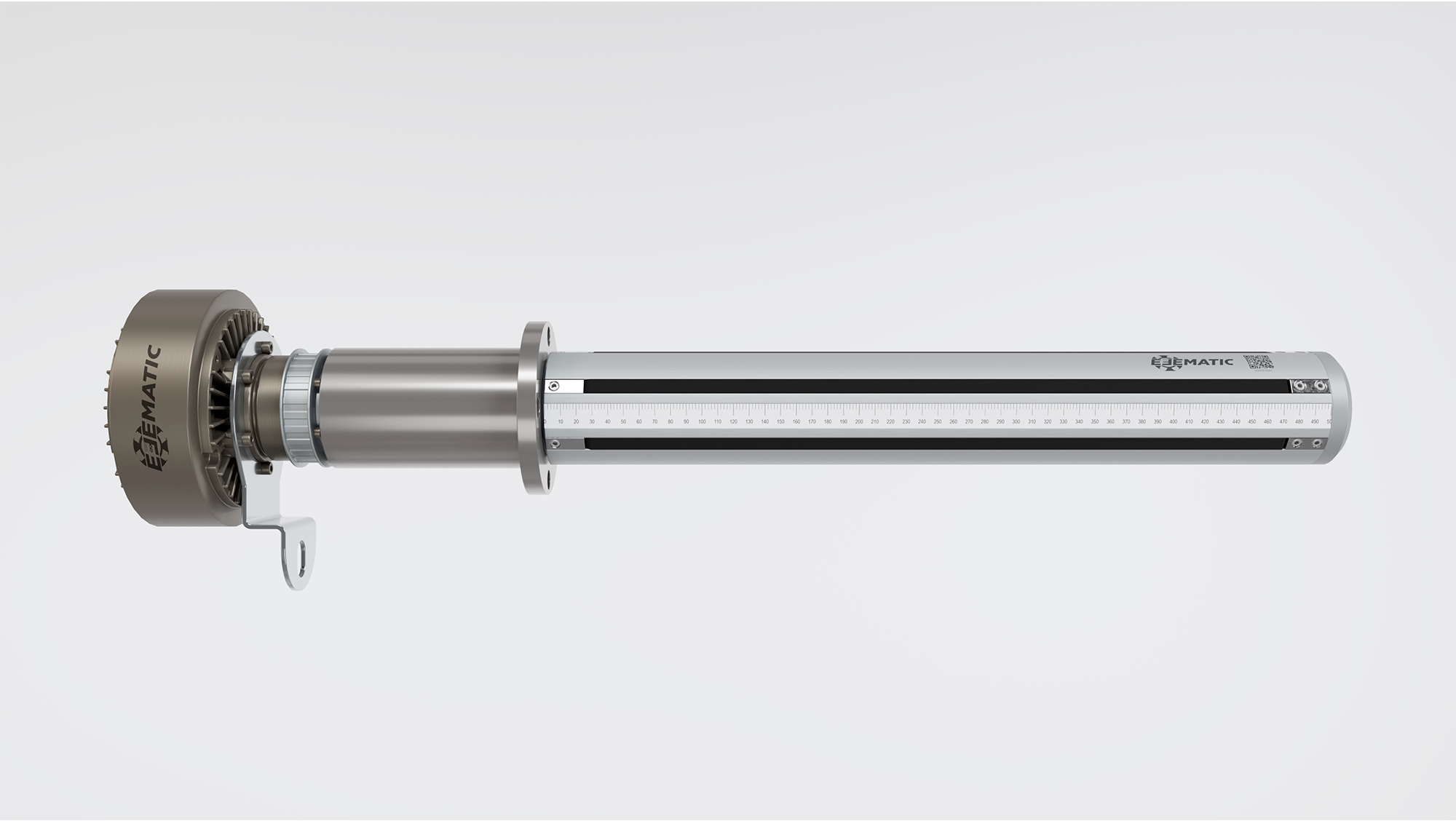

A 24V power supply connection is required. The clutch receives a 0-10V signal, manually regulated by a potentiometer or via PWM electronics, which manage sensor data and adjust tension for precise real-time web tension control.

In these systems, regulation can be carried out manually by the operator or via a specialized sensor measuring the roll diameter. It is important to note that these systems lack feedback, meaning there is no automatic mechanism to correct the control action in real-time.

This type of system usually employs devices like dancers or load cells to monitor material tension. These devices compare the measured tension with a preset reference value. Thanks to this setup, superior process control accuracy is achieved, enabling automatic adjustments based on detected differences.